A curtain wall system is a light weight exterior cladding which is hung on the building structure, usually from floor to floor. It can provide a variety of exterior appearances but is characterized by narrowly spaced vertical and horizontal caps or metal infill panels. These systems provide a finished exterior appearance and most often a semi-finished interior as well. They are also designed to accommodate structural deflections control wind-driven rain and air leakage, minimize the effects of solar radiation and provide for maintenance free long term performance. Most of today’s metal curtain wall systems are constructed of light weight aluminium although some may be of steel.

The different types of curtain wall are:

- Conventional Stick System

- Unit Mullion System ( Semi Unitised )

- Unit Panel System (Fully Unitised )

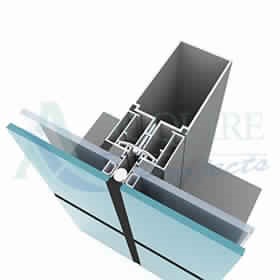

Conventional Stick System

- Vertical “Mullions” and Horizontal “Transoms” are installed on brackets anchored to the slab or beam of structural.

- The Glass is fixed in the grid work with pressure plates (The glass is glazed mechanically).

- This system comprises of off the shelf components assembled on site .

- Can be accommodated for varying site conditions.

- Cost of the System is relatively Low.

- High field costs.

- Longer installation period because the system is entirely assembled on site.

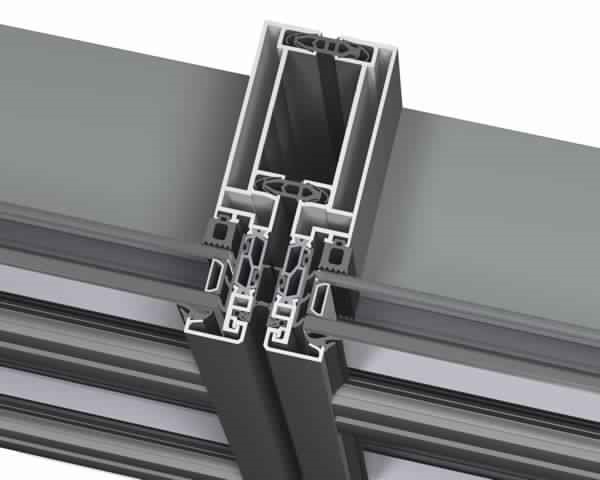

Unit Mullion System (Semi-Unitised System)

- In this system the vertical mullions and horizontal transoms are installed on brackets anchored to structural slab or beam.

- Glass is structurally glazed to the aluminium sub frame by structural sealant & these sub frames are then fixed in the grid work.

- The system offers some of the factory quality control of the unitized system.

- Little less cost, and a shorter lead time because there is less customization than a fully unitized System.

- Field labor time and erection costs are more in line with the stick system.

Unit Panel System (Unitized System)

- In this system brackets are anchored to the columns/slabs after detailed site survey.

- The complete unit spanning floor height fully fabricated at the factory is installed on the brackets.

- In this system 10% of the work is done at site.

- This system comes pre-assembled; it can be pre-glazed at the factory or shop, or glazed on-site.

- Minimizes field labor and erection costs, and promises a shorter installation period than the stick system.